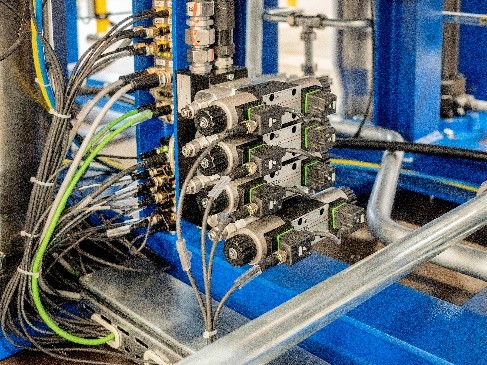

Decentralization makes this successful machine concept even better The HF Group has developed the Curemaster PCR, a high-performance tire press for passenger cars. It excels at evenly distributing the pressure. The system's slim design reduces floor space requirements, transportation costs and energy consumption, and makes the machine easily accessible for operation and maintenance. And the Curemaster PCR can be installed quickly. But HF's decision-makers were not entirely satisfied. "We wanted to increase the level of digitalization and make the system concept more modular," explains Warren Rudman, Vice President HF Group. The option under consideration was a new, decentralized automation concept. Ideal complementation The main advantage of decentralized automation concepts: They are extremely efficient. The control and drive technology are located close to the machine, providing flexible and scalable solutions for all applications. This reduces the complexity of bulging control cabinets. This saves time and effort during installation – and therefore costs. With IO-Link, decentralized automation architectures can be implemented perfectly. The internationally standardized communication system ensures that intelligent sensors and actuators are connected to automation systems. To implement the new concept, HF Group needed a suitable partner with in-depth know-how and a wealth of experience in designing and implementing a decentralized automation concept: Murrelektronik. The starting signal for the system design was given at the beginning of 2024. In February, a team from Murrelektronik visited a Curemaster PCR fair +machine at the HF Group in Hamburg-Harburg. "That was very exciting. The machine was set up like this about five years ago and had not been changed since. Some of the machine's functions were unknown," says Michael Henn, Application Engineer at Murrelektronik, with a grin. It was a challenge that we took on immediately. Before starting, the Murrelektronik team determined the product requirements and modules, defined the concept, and delivered the first components to the HF Group. Successfully avoid all pitfalls In just five days on site, Murrelektronik's four-person team adapted the installation concept several times to accommodate previously unknown information and then successfully implemented it together with the HF Group team. It was an intense week with some unforeseen challenges. However, everyone is satisfied with the way the project has gone and with the result: "The Murrelektronik team did a great job. The Curemaster PCR is now IO-Link capable and future-proof," Warren Rudman is pleased. Thanks to plug and play, wiring is now much easier, it takes now just 60 hours instead of around 200 hours. Diagnostic reliability has also been significantly improved – true to the motto "finding errors instead of searching for them". For example, a defective cable can now be diagnosed and replaced much more easily. The system stores parameters for each device, so that replacement is possible without having to set up the parameters again. Furthermore, significantly fewer cables are needed overall. Thanks to the decentralized concept, the control cabinet is now only about half the size it used to be. Pictures: A great success: Murrelektronik's new decentralized installation concept, based on highly flexible IP67 modules and double valve connectors, reduces the time required for wiring from around 200 hours to just 60 hours. "The Murrelektronik team did a great job. The Curemaster PCR is now IO-Link capable and future-proof," says Warren Rudman, Vice President HF Group (left, in picture with Wolfgang Wiedemann, Director Application Sales Consulting of Murrelektronik). About the HF Group: About Murrelektronik: Press contact: Harburg-Freudenberger Maschinenbau GmbH Murrelektronik GmbH

Perfect cooperation

HF Group is a leading company in the field of tire manufacturing and tire technology.

Headquartered in Hamburg, Germany, with additional offices and production facilities around the world, we develop innovative solutions for the tire industry. Our product range includes machines and equipment for tire production that meet the highest quality standards. We focus on sustainability and efficiency in all our processes and strive to offer our customers not only first-class products but also tailor-made solutions. Through continuous research and development, we remain at the forefront of technical innovation and actively contribute to the advancement of the tire industry. With a dedicated team of experts and decades of experience, we are the reliable partner for tire manufacturers worldwide. HF Group stands for quality, precision and progress. Learn more here: www.hf-group.com

Making industrial automation as simple, seamless and cost-efficient as possible with smart solutions: Murrelektronik is the forerunner in decentralized electrical automation technology and has become, based on this DNA, the leading company in this field. Murrelektronik's solutions bring signals, data and power close to the process, eliminating the need for control cabinets. For almost 50 years, more and more customers worldwide from all manufacturing industries have placed their trust in this special expertise. Headquartered in Oppenweiler, Germany, the successful family-owned company has an extensive network of over 3,200 experts in more than 50 countries. With several global production and logistics locations, Murrelektronik is close to its customers to solve their diverse challenges quickly and smartly. The company has continued to expand its portfolio and covers a wide range – from connectors to I/O systems, power supplies and network technology up to the fast and easy installable, modular complete solution for cabinet-free automation, called Vario-X. As part of the plug and play mindset, Murrelektronik also offers holistic digital services supporting installation, commissioning and maintenance. Learn more here: www.murrelektronik.com

Nora Grupe

nora.grupe@hf-group.com

www.hf-group.com

Mark Böttger (Head of Corporate Communications)

Phone +49 174 658 1660

mark.boettger@murrelektronik.de

www.murrelektronik.com